Exterior Wall Thickness: How Thick Should Your Walls Be?

The exterior walls of a house serve several vital functions. The walls enclose the structure, keep the weather out, and minimize the heat or cool air exchange between the interior and exterior of the home. Exterior walls also provide a sound barrier against outside noises from traffic, planes, etc. Load-bearing exterior walls carry the structure's compression (vertical) loads down to the foundation. In areas prone to natural disasters like seismic activity and hurricanes, exterior wall designs must include shear wall systems that resist lateral loads (horizontal forces) down to the foundation.

The exterior wall width plays a significant role in achieving an energy-efficient, disaster-resistant home with good indoor environmental quality (IEQ).

How Thick Should Exterior Walls Be?

Standard exterior wall thickness varies, depending on the framing material and exterior finishes.

Wood-framed Exterior Wall Thickness in Inches

When wood framing a home’s exterior walls, builders often use two- by four-inch studs. However, to achieve high-performing, disaster-resistant exterior walls, builders need to increase the exterior wall dimensions using two- by six-inch studs, which increases the exterior wall thickness to just under 5.5 inches plus 5/8" sheathing:

2- by 6-inch studs create a thicker wall, providing extra space for insulation, making a home more energy-efficient (R-13 vs. R-20), comfortable, and soundproof. The thicker walls also give space to insulate the headers, further increasing the R-values.

2- by 6-inch studs with sheathing improve the exterior wall’s comprehensive strength, making them considerably stronger against lateral loads, resisting bending and buckling during earthquakes and tornadoes.

Unfortunately, framing with 2- by 6-inch studs vs. 2- by 4-inch studs comes with a few drawbacks:

Framing with 2- by 6-inch studs can add 40 percent to a project's lumber costs - a significant problem today due to lumber shortages and volatile and increasing costs. Adding more insulation improves the wall’s energy efficiency, however, rising insulation prices further threaten the bottom line of building projects.

To compensate for thermal bridging at the studs, exterior insulation (either 1" or 1.5") is added, which increases the overall wall thickness.

Moisture may accumulate inside the thick walls when the warm indoor and cold exterior air collides, leading to rot and decay of the framing, along with unhealthy mold, which diminishes the home’s IEQ.

Wood framed exterior walls require air sealing, air barriers and vapor retardant membranes.

Builders find the larger studs harder to lift, and the headers require more work.

The quality of framing members, moisture content, warping, waste, etc. has always been an issue.

Insulated Concrete Form Exterior Wall Thickness Residential

How thick are exterior walls when using insulated concrete forms? Ask an expert.

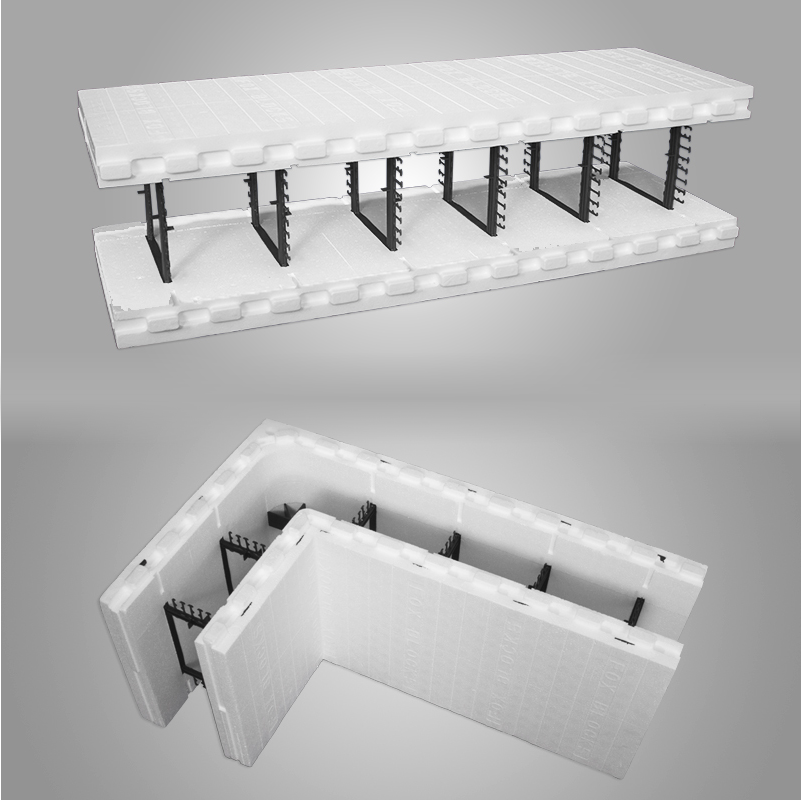

Determining the thickness of a residential above grade exterior insulated concrete form walls is detailed in the building code and by ICF manufacturers engineering tables. ICF construction includes the double layer of polystyrene (EPS) insulated blocks stacked into the shape and dimensions of the exterior walls. As the ICFs are placed, steel rebar is installed horizontally and vertically before concrete is placed in the blocks.

The Benefits of ICF Exterior Walls

ICF construction produces disaster-resistant, energy-efficient, durable exterior walls that contribute towards excellent indoor environmental quality (IEQ).

The concrete thickness of the ICF wall provides superior disaster resistance against severe winds and earthquakes.

The foam thickness of the ICFs creates R-values that exceed ASHRAE/ANSI 90.1 energy code requirements.

Moisture-resistant ICFs help to minimize the growth of damaging and unhealthy mold.

The concrete and insulation provide excellent sound dampening.

ICF exterior walls provide both air and vapor resistance without additional membranes.

Determining a Typical Exterior Wall Thickness For ICF Construction

The thickness of exterior residential walls when using ICFs depends on several factors. Standard ICF external walls need six inches of concrete. However, areas susceptible to high winds require concrete thickness of at least 8 inches. The engineering tables review several characteristics of the building's design and location when establishing the concrete core size and the rebar layout.

The above-grade ICF walls' design considers local wind and seismic loads along with dead and live floor, and roof loads.

ICF reinforced concrete walls exceed wood framed walls as shear walls.

The wall height and the wall’s fire resistance and sound ratings also affect the wall thickness.

The thicker walls also have deep window sills that increase lighting and character to the house's interior.

Design Considerations for the Thickness of ICF Walls

Essentially all home and building designs can accommodate ICF construction.

However, the standard thickness of ICF exterior walls is 12 inches, reducing room sizes and minimizing the home's square footage. To maintain the original square footage of a building plan, you must increase the overall dimensions of the house, which also impacts the design of the roof and foundation. In addition, doors and windows require wider jamb extensions. Modifying traditional building plans to ICF construction costs about $1,000.

Achieve Optimal Exterior Wall Thickness with Fox Blocks ICF Walls

The average exterior wall thickness of Fox Blocks ICF construction helps homeowners achieve their goals for building an energy-efficient, disaster-resistant, and durable home with excellent IEQ:

Fox Blocks, with an R-value of 23, needs 44 percent less energy to heat and 32 percent less energy to cool than wood-framed houses.

Disaster-resistant Fox Blocks ICFs, with steel-reinforced concrete, provide significant strength against severe winds exceeding 200 mph and projectile debris traveling over 100 mph.

Moisture-resistant Fox Blocks ICFs provide a solid continuous monolithic concrete wall with a perm rating below 1.0, controlling moisture intrusion and prohibiting the growth of damaging and unhealthy mold and mildew.

Fox Blocks lack organic material, which pests like termites eat. However, Fox Blocks recommends Polyguard Products, Inc. 650 XTM or 650 XTP membranes for termite and waterproofing protection.

Fox Blocks Series ICF provides high sound reduction, receiving a high ASTM E90 Sound Transmission Classification (STC) rating of more than 50.

Fox Blocks ICFs eliminate the need for expensive material and labor for air barrier and weather resistant membranes.

Learn More About Making the Switch to ICF

The exterior wall thickness of a home significantly impacts the house’s energy efficiency, disaster resistance, and IEQ. Thicker ICF exterior walls create high-performing, long-lasting, durable, safe, and comfortable homes, with none of the problems associated with 2- by 6-inch wood frame exterior walls: high lumber costs, moisture issues, and application challenges.

Fox Blocks makes the change from wood to ICF easy with our online training on the Fox Blocks Integrated Learning Center website, technical documentation on the main website Resources, and the EstimatorPro material estimating program. Our experience shows that once a builder switches to Fox Blocks ICF wall systems, the ease and quickness of its installation make them want to stop framing exterior walls with wood.

Contact the exterior wall experts at Fox Blocks today for more information on the benefits of ICF.