Rebar Sizes, Grades, and Types: Building Strength and Stability

Every structure, from towering skyscrapers to quiet family homes, relies on rebar to provide the strength and stability that concrete alone cannot deliver. Selecting the correct rebar sizes, grades, and types helps builders create structures that are not only durable but also capable of withstanding extreme conditions. Understanding these elements ensures projects meet the demands of modern construction while supporting long-term resilience.

Historical Evolution of Rebar

The history of rebar reveals how advancements in materials and engineering have transformed construction practices over time.

From Ancient Materials to Modern Innovation

The concept of reinforcement dates back to ancient civilizations. Builders used materials like bamboo and wood to fortify structures, offering rudimentary tensile strength. The 19th century marked a pivotal shift with the introduction of iron and steel reinforcements. Innovations such as twisted iron bars by Ernest L. Ransome laid the foundation for modern rebar.

By the 20th century, standardization efforts, like those spearheaded by ASTM International, ensured consistency in rebar production and quality, enabling advancements in construction technology.

These early developments paved the way for today’s innovations, including high-strength grades such as Grade 100 and non-corrosive materials like glass-fiber-reinforced polymer (GFRP) rebar. Modern rebar technology continues to push the boundaries of durability and resilience, supporting the demands of contemporary construction.

Understanding Rebar Sizes

Rebar sizes are classified using a numbering system that reflects their diameter, weight, and strength, making it easier to select the right option for each project.

Rebar Size Designations

Rebar sizes are indicated by a numbering system, with numbers such as #3, #4, and #5 corresponding to nominal diameters measured in eighths of an inch. For instance, #3 rebar has a diameter of 0.375 inches (or ⅜”). These designations are critical for determining a rebar’s cross-sectional area, weight per unit length, and load capacity.

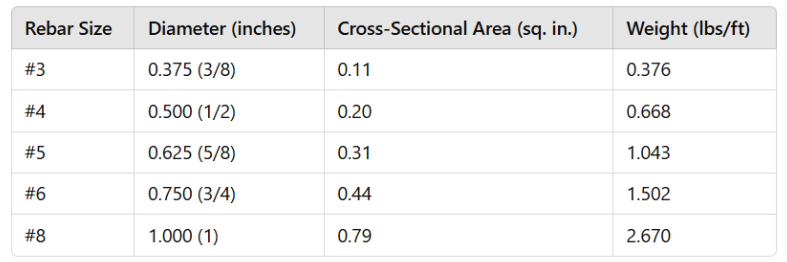

Rebar Size Chart

Here’s an expanded reference chart for common rebar sizes:

Cross-sectional area determines load-bearing capacity, while weight per unit length affects installation requirements.

Selecting Sizes for Specific Applications

The appropriate rebar size depends on the structural requirements and load distribution of the project:

Residential Projects: #3 and #4 rebar are commonly used for patios, driveways, and light structural work.

ICF Residential: #4 and #5 are typically used for ICF below and above grades wall assemblies

Medium-Scale Construction: #5 and #6 rebar are ideal for retaining walls, columns, and beams.

Large-Scale Infrastructure: #8 rebar and larger are used for high-stress structures like bridges, dams, and high-rise buildings.

Using the correct rebar size ensures efficient load distribution, enhances structural stability, and reduces the risk of failure.

Rebar in ICF wall assemblies is typically installed horizontally and vertically as per engineering design specifications and/or the IRC code tables, for commercial buildings as per ACI 318. In some applications, such as seismic zones and a double layer of horizontal rebar may be installed.

Exploring Rebar Grades

Rebar grades indicate the material’s strength and flexibility, ensuring it meets the demands of various structural applications. Each grade is defined by its yield strength, measured in pounds per square inch (psi).

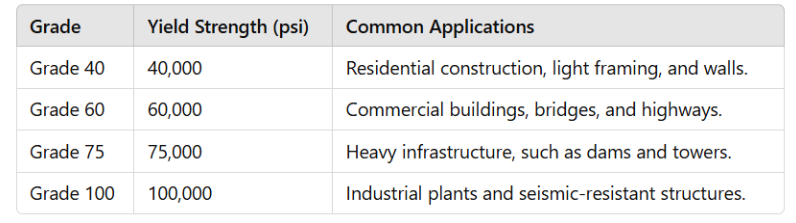

Common Grades

Here are the most commonly used rebar grades:

Application-Specific Grades

Rebar grades are selected based on the structural demands and environmental conditions of a project. Each grade offers a specific balance of strength and flexibility, making it suitable for distinct applications:

Grade 40: Used for lighter residential projects, such as house foundations, footings, and driveways, where minimal stress is expected.

Grade 60: Popular across general construction due to its strength and cost-efficiency, making it ideal for commercial buildings, bridges, and highways.

Grade 75: Commonly required in large-scale infrastructure projects, such as high-rise buildings, retaining walls, and transportation networks, where enhanced load capacity is critical.

Grade 100: Reserved for specialized applications, including industrial plants, seismic-prone areas, and high-stress structures demanding exceptional durability.

Performance Under Environmental Conditions

Different grades of rebar offer varying resistance to environmental factors:

Lower grades like Grade 40 may deform under heavy loads in extreme heat or cold.

Higher grades such as Grade 75 and Grade 100 are engineered for environments with high stress, such as earthquake-prone regions.

ASTM Standards for Rebar Grades

Rebar grades are governed by ASTM standards to ensure consistency and reliability:

ASTM A615: Covers carbon steel rebar, including Grades 40, 60, and 75.

ASTM A706: Specifies requirements for weldable rebar, often used in seismic-resistant structures.

ASTM A1035: Defines high-strength rebar, such as Grade 100, for demanding applications.

Understanding and selecting the appropriate grade ensures the rebar can handle the specific stresses and conditions of a project, contributing to long-term safety and durability.

Types of Rebar and Their Applications

Different types of rebar are designed to address specific environmental challenges and structural needs, offering solutions for a wide range of construction projects.

Carbon Steel Rebar

Carbon steel rebar is the most commonly used type due to its affordability and high tensile strength. It is ideal for general construction but lacks corrosion resistance in high-moisture environments.

Epoxy-Coated Rebar

Specified under ASTM A775, epoxy-coated rebar features a corrosion-resistant coating, making it ideal for marine structures, parking garages, and bridges. However, it must be handled carefully to avoid damaging the coating.

Stainless Steel Rebar

Highly corrosion-resistant and durable, stainless steel rebar is suited for long-term, critical infrastructure projects. Though more expensive, its longevity makes it cost-effective in the long run.

Galvanized Rebar

Galvanized rebar is coated in zinc to resist rust, suitable for wastewater facilities and agricultural environments. It offers a mid-range corrosion solution between carbon steel and stainless steel.

Glass-Fiber-Reinforced Polymer (GFRP) Rebar

GFRP is a non-metallic, non-corrosive option made from glass fibers and polymer resin. It’s ideal for MRI rooms or electrical substations where magnetic interference must be avoided.

By selecting the right type of rebar, builders address structural demands while supporting sustainable construction practices focused on long-term resilience.

Refer to ICF manufacturer specifications for typical rebar sizes, types, and grades, along with spacing that suits ICF block dimensions.

Rebar and Resilient Building Design

The use of rebar in resilient building practices ensures long-term durability and protection against environmental and structural stresses.

Structural Strength and Impact Resistance

Rebar-reinforced ICF systems provide exceptional strength and impact resistance, helping structures withstand natural disasters such as hurricanes, earthquakes, and flooding. The combined benefits of reinforced concrete and ICF blocks create solid, disaster-resilient walls capable of protecting occupants and preserving building integrity.

Long-Term Durability

Integrating rebar with ICFs enhances the life cycle of buildings by preventing structural degradation over time. Whether it's resisting corrosion, absorbing seismic shock, or withstanding high winds, the durability of rebar-reinforced ICF construction supports long-lasting, low-maintenance structures.

Build Smarter with Fox Blocks

Fox Blocks insulated concrete forms provide an ideal framework for incorporating rebar into durable, resilient structures that promote occupant safety and long-term performance. These advanced ICF systems support disaster-resistant construction and ensure projects are built to last.

By combining thermal mass, structural integrity, and long-term durability, Fox Blocks ICFs are the smart choice for modern building projects.

Contact us today for more information!